HVAC notes

^TOC

Everything I've learned about HVAC so far

Friction rate

Air flow (CPM)

Air velocity (FPM)

Total External Static Pressure (TESP)

Available Static Pressure (ASP)

Total Effective Length (TEL)

Temperature Rise

Load

Temperature rise test

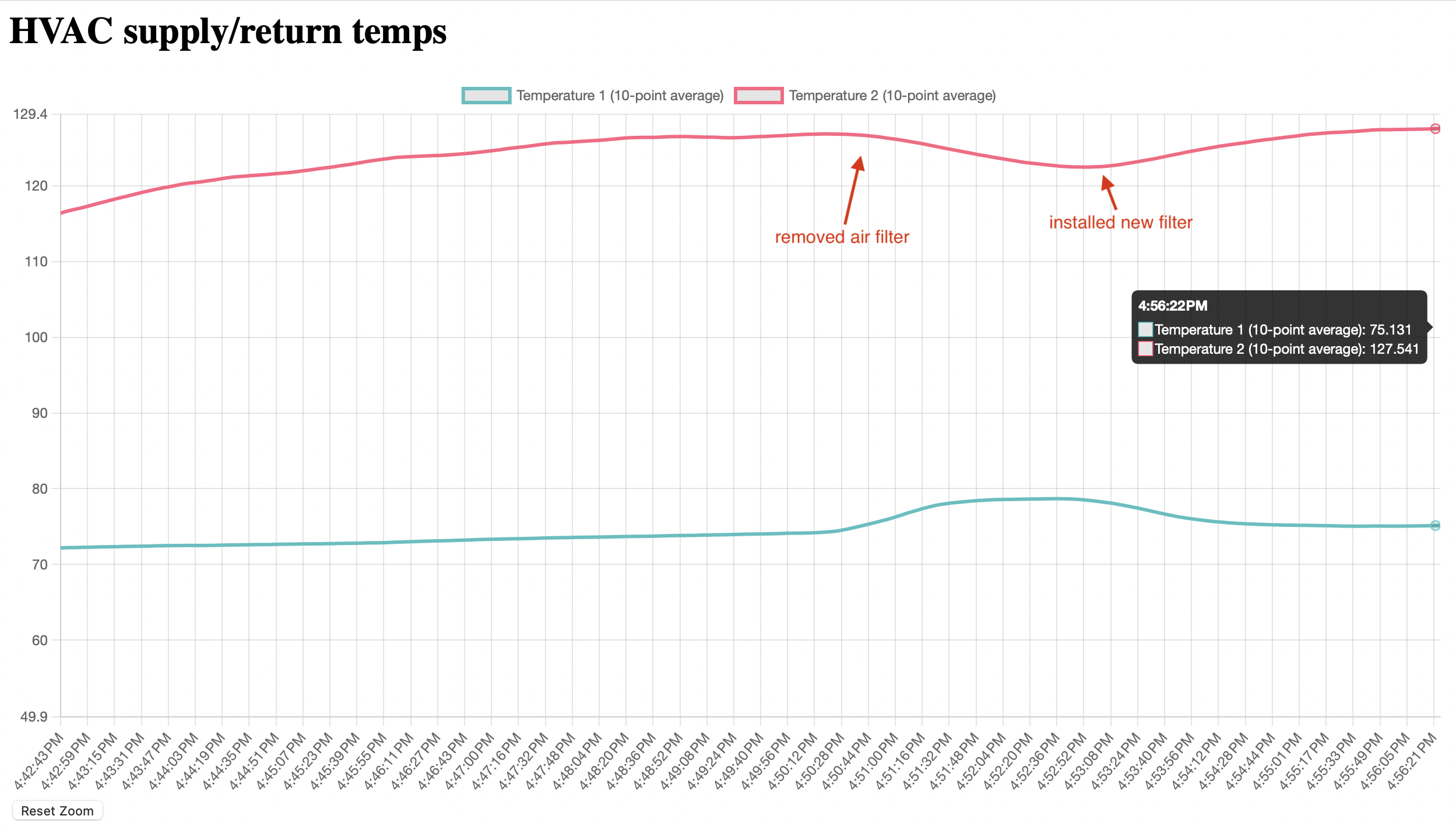

Just used 2 K-type thermocouples to do a temp rise test. I don't have to bead type so the response is slower but it should work well enough.

I drilled two small holes: one right after the 90 degree bend from the supply at the top and one right after air filter in the return. I put the thermocouples in there, turned on the furnace, and recorded data for ~10 minutes:

I still don't fully understand how temp rise is related to air flow, but what's interesting is removing the air filter had a noticeable impact on temp rise. It reduced it by about 7 degrees! Clearly this stuff does work. I think improving air flow allowed the furnace to produce more hot air into the system (which comes back into the return and reducing the temp difference).

I have a temp rise of ~52 deg (an estimate given my rough measuring). The specs on my furnace list a temp rise range of 25-55, so I'm just at the upper bounds.

If I use the CFM equation of out BTU / (temp rise * 1.08) I get 61,000 / (52 * 1.08) which is a CFM of 1,086.

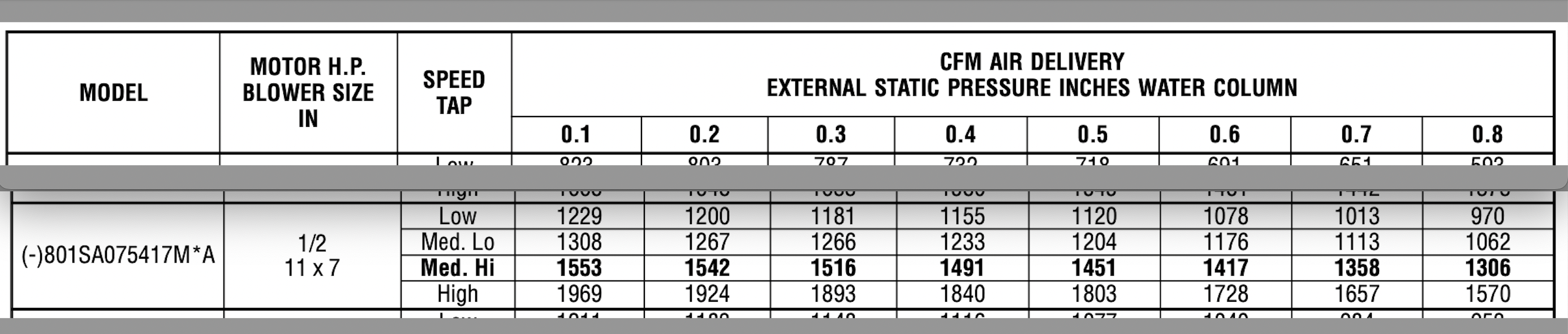

Here is the fan chart for my machine (I cropped out all other models):

I don't know what the static pressure is yet (I've ordered a manometer), but even at the highest pressure I should be getting 1306 assuming the blower is set to the default med. hi. I actually tried to get a quick pressure test with a clear tube and some water and I read 0.8 just on the return side, and you're supposed to add in the supply side as well.

I have a sense that my system is too constricted and not getting as much CFM as it should. Once I get a real manometer I'll measure the static pressure and go from there.

Notes

- My main trunk line is 12x16" duct

- Spec sheets

- Downstairs

- Gas furnace (R801SA075417M)

- Air handler (RCF3617STAMCA)

- Upstairs

- ???

- Downstairs

- Manometer measures pressure

- Use it to measure the total static pressure in the system

- Pitot tubes improve accuracy

- Once you have static pressure you can look up the CFM in the fan chart in the spec sheet

- You want to measure static pressure in multiple places

- To get total static pressure, measure right after blower (before cooling coils) and measure right after air filter and sum together

Links

- My reddit post about temp rise question: https://old.reddit.com/r/hvacadvice/comments/1f1te2q/is\_temp\_rise\_dependent\_on\_outdoor\_temp/

- Adjusting fan speed on rheem furnace: https://www.youtube.com/watch?v=JdRBpWYwrnY

- https://www.acservicetech.com/post/finding-an-airflow-problem-using-static-pressure-measurements

- https://www.bradleymechanical.com/resources/manual-j-s-d-t

- Duct Design 2 — Available Static Pressure

- https://www.energyvanguard.com/blog/duct-design-3-total-effective-length/

- calculator:

- HVAC Duct Calculator | Duct Size Calculator

- TEL: 160?

- friction rate: .154? (should write down what this is)